Application:

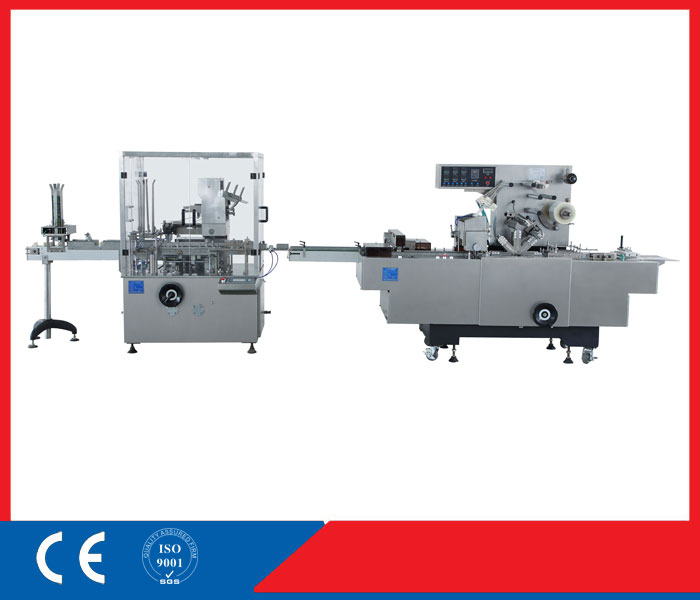

Model DZ-120B Cartoner machine is suitable for packing blister cards.On line product feeding and detecting,leaflet fold(1-4folds) and feeding,leaflet detecting,canton opening and forming,products and leaflet pushing into carton,printing batch number,sealing carton with tuck-in or hot melt glue device. Automatically reject lacking of leaflet or product and finished product out.

Features:

1: International famous brand of electrical component such as PLC touch screen, frequency inverters, etc.

2: Adopt human-machine operation system.

3: Automatically stop when machine is overload.

4: Automatically reject lacking of package product and leaflet.

5: Automatically display trouble,Alarm and count finished products.

6: Stable performance,operation is easy.

Parameter:

| Item | Parameters | |

| Encasing speed | 60-80 boxes /min | |

| Box | Quality requirement | 250-350g/m2[Base on carton size] |

| Dimension range(L×W×H) | (65-160)mm×(30-130)mm×(14-55)mm | |

| Leaflet | Unfolded leaflet specification | (80-230)mm×(90-170)mm |

| Fold range | [1-4]Fold | |

| Compressed air | Working pressure | ≥0.6mpa |

| Air consumption | 120-160L/min | |

| Power supply | 380v 50HZ | |

| Main motor power | 0.75kw | |

| Machine dimension(L×W×H) | 2400 X 1140 X 1800mm | |

| Machine weight | 1000kg | |

BT-2000L Model overwrapper machine

Suitable for packing carton with bopp film

Suitable for connecting other packing machine together.

| SIZE RANGE (IN MM) | MIN. STANDARD | MAX. STANDARD |

| Length (L) | 40 | 200 |

| Width (W) | 30 | 140 |

| Height (H) | 10 | 80 |

| Maximum output * | 40-80strokes per minute | |

| Film width | 60-260MM | |

| Voltage | 220V 50HZ ,ONE PHASE | |

| Power | 4KW | |

| N.weight | 900Kg | |

| Film-roll diameter max. | 320 mm | |

| Packaging material | Polypropylene,Bopp | |

| Basic configuration | HOPPER INFEED | |

| OVERWRALL DIMENSION | 2600X960X1600MM | |

| Optional accessories | PLC controller ,touch screen, printmark registration, Date printer, safety cover, conveyor belt. | |

* depending on product, machine configuration and packaging material