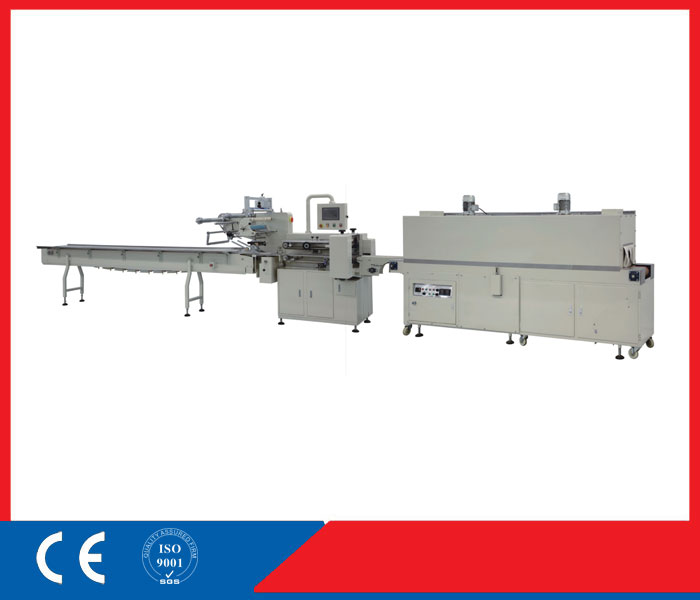

Featrues:

Compact structure, stable function and simple operation.

The first third-generation double frequency control the bag could be set and cut,unnecessary adjust air without changing film color code tracking one pace reaches the designated position,it’s saving time and film.

It adopts imported electric appliance, touch man-machine interface, convenient parameter setting.

Self-checking function, trouble can be read easily. High sensor photoelectric color chart tracking, make the cutting position more correctly.

High sensor photoelectric color chart tracking,make the cutting position more corretly

Dependant temperature PID controlling suitable for various materials of packagingmenbrane.Position stop function, no adhesive and no waste of membrane.

Clean rotation system, more reliable operation and more convenient maintenance.

All the controlling operates by the software,convenience for function adjustment and technical up grading.

Main Technical Data

| Model | KD-260B | KD-350B |

| Max.film width | 260mm | 350mm |

| Max packaging capacity(according to its material to fix) | 50-220p/min | 50-220p/min |

| Suitable film thickness | 0.03-0.06mm | 0.03-0.06mm |

| Length of bags | 60-330mm | 80-350mm |

| Packaging with | 25-100mm | 50-200mm |

| Packaging height | 5-45mm | 10-70mm |

| Intensity of Sealing | ≥15 | ≥15 |

| Total power | 2.4Kw 220V 50hz | 2.7Kw 220V 50hz |

| Overall dimensions(L x W x H) | 4100x920x1500 | 4000x1000x1500 |

| weight | 600kg | 680kg |

Samples

|